What is AQL Breaking Down the Basics

AQL stands for Acceptable Quality Limit, a key term in quality control and inspection. According to the ISO 2859-1 standard, AQL defines the maximum number of defective items that can be considered acceptable during random sampling of a product batch. Think of it as a tolerance level that balances product quality with practical inspection efforts.

Originally, AQL was often referred to as an inspection “Level,” but over time, the focus shifted from how much you check to the quality limits you set. This evolution helped clarify that AQL isn’t about catching every single defect but ensuring defects stay within an acceptable boundary.

Defects are generally classified into three categories:

- Critical defects: These pose safety risks or make the product unusable.

- Major defects: These affect function or marketability, but don’t make the item dangerous.

- Minor defects: These are small issues that don’t affect usability but may impact aesthetics or customer satisfaction.

AQL is vital because it helps businesses keep inspection costs manageable while maintaining quality that meets customer expectations. Without a clear AQL, companies risk spending too much on 100% checks or, worse, shipping poor-quality products that harm their brand. It strikes the right balance to protect both budgets and reputations.

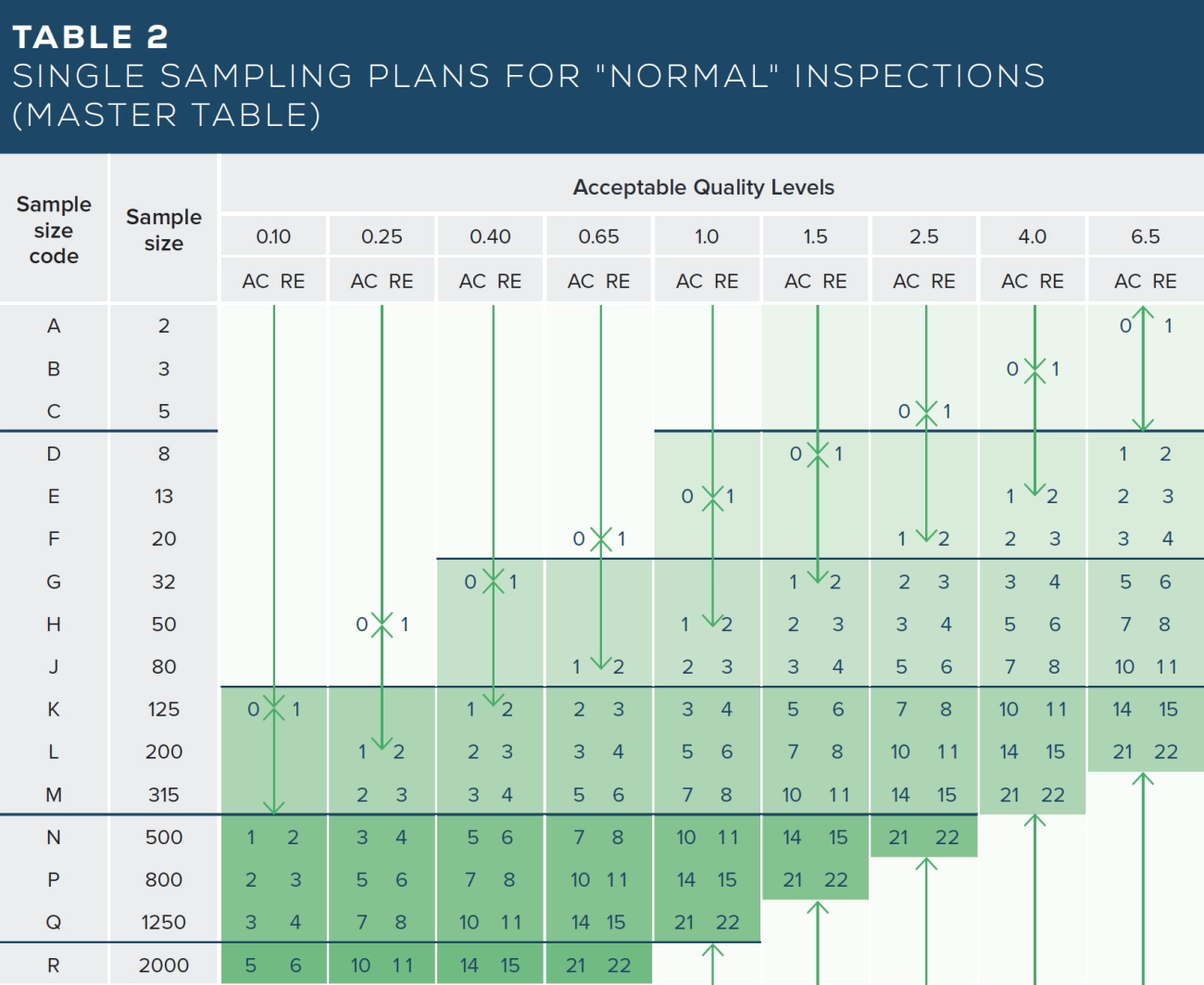

Use AQL tables to select sample size

With batch size and inspection level set, consult an AQL table. This will tell you how many pieces to pull from the batch for inspection.

Set acceptance and rejection numbers

The AQL table also gives you limits: how many defects are acceptable (acceptance number) and when to reject the batch (rejection number).

Common pitfalls and defect misclassification

Watch out for mixing up critical, major, and minor defects. Misclassifying defects can lead to wrong decisions—either passing bad products or rejecting good ones.

Example walkthrough for apparel order

Imagine you have a batch of 1,000 t-shirts. You choose an inspection level II (standard) and an AQL of 2.5. The AQL table says inspect 80 units. If you find 4 or fewer defective shirts (major or minor defects combined), you accept the batch. More than that, and you reject it.

REPA resource free sampling checklist

To make AQL sampling easier, REPA offers a free checklist that guides you through sample selection, defect classification, and recording results. This ensures your inspection process is clear, consistent, and on point.

Using a solid AQL sampling plan like this keeps your quality inspection systematic and reliable, balancing cost and quality effectively.